Method for Efficient Mass-Production of Surface Textures

Description:

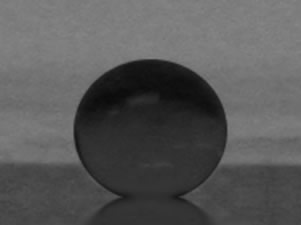

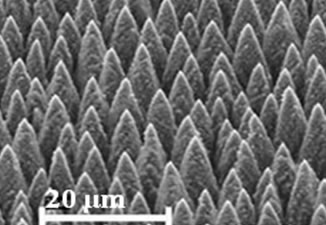

Courtesy of Gupta laboratory

| Microscopic view of a laser

micro-textured surface. |

Background

Surface texturing has become an important tool

for enhancing surface properties, particularly in fields such as solar and wind

energy, aeronautics and medicine. Surface texture is typically generated by

chemical etching, a costly and time-consuming process that is known not to be

very effective for polycrystalline and thin film semiconductors.

Invention Description

Researchers at the University

of Virginia have developed novel methods for generating micro- and nano-textured

surfaces on a variety of materials — including metals, semiconductors and

insulators — using pulsed laser technology.

Using this innovative

method, a clean surface specimen is simply placed on a staging platform, and a

laser scans over the surface, generating the surface texture and thereby

enhancing the surface properties. This surface texture can then be mass-produced

by applying industrial manufacturing scale-up techniques or — if the substrate

material can be a PDMS film — through embossing.

Advantages

This surface-processing method is

advantageous for several fields in which surface properties play a vital role.

Using this cost-effective, low-environmental-impact method, surfaces can be

generated that:

- Are super-hydrophobic, for enhanced fluid flow, for

anti-icing on wind turbines or airplane wings, and other desired uses.

- Offer enhanced light-trapping abilities, for increased

efficiency in photovoltaics.

- Have larger surface areas, which can enhance heat

transfer, catalytic activity, adhesive bond strength and tissue growth

(biomedical applications).

- Contain sharp geometries, which can enhance field

emissions and thin film/fiber growth.

Patent Information:

| Title |

App Type |

Country |

Serial No. |

Patent No. |

File Date |

Issued Date |

Expire Date |

Patent Status |

|

|

|

Inventors:

Keywords:

|